1-800-805-5783

1-800-805-5783

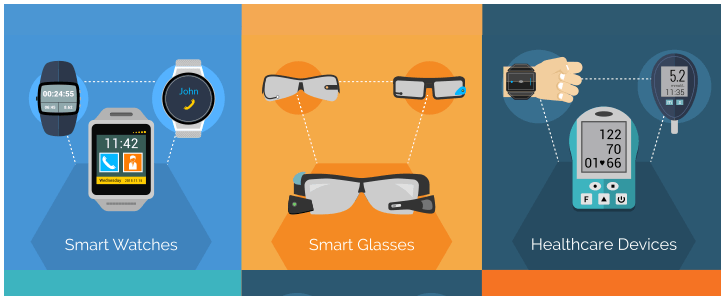

The manufacturing industry is excited about leveraging wearable tech in the shop floor. Already many companies are using wearable devices for product design & development, employee training and security etc.

As per a research by Goldsmiths and Rackspace, productivity of workers across 85 companies increased by 8.5%, and job satisfaction levels rose by an average of 3.5% with the use of wearables.

Wearables brings a range of benefits for manufacturers but at the same time it also brings a few challenges, especially in a sector like manufacturing which involves high degrees of risk, costs, and requirement for precision.

The basic challenge is the affordability of the wearable tech. The average price of wearable devices are around $1500 (whereas for consumer products the average price is $300).

Yes as much as safety is an opportunity it is also a challenge in manufacturing. You don’t want your employees to have something which may restrict their vision or distract them while working on a heavy machine. Operating the device with gloves on also becomes a challenge.

Wearable tech uses modern devices like sensors, Bluetooth, GPS, storage chips which consume a lot of power. Power backup thus becomes a challenge in manufacturing where people work for long hours without access to recharge points.

The success of wearable lies on how the wearable is able to replace a conventional device. In a manufacturing setup where workers are working in extreme spots like under machines or on cranes you don’t want to burden them with extra devices. The user should not feel burdened or uncomfortable while using wearables. The device should be robust enough to absorb all types of vibrations, dust, dirt, temperatures, etc., that it is exposed to.

Enterprises are vary of the fact that confidential data would be at risk as the data is stored on a cloud or transferred through Bluetooth. The biggest challenge of wearable tech providers would be to ensure privacy and security of the clients. A lot of employees would also not want their privacy being tracked with the location tracker on the device.

Wearable device manufacturers and other stakeholders have to quickly address these challenges to make it more adoptable in the industry. Once done, it will help the industry achieve higher productivity, precision and safety.

Wondering how best you can use wearable tech for your business? Get market trends and expert insights on wearable tech in manufacturing by downloading our latest eBook.

Tags: wearable tech