An Introduction to Lean Startup and its Impact on Product Development

Companies today constantly seek innovative ways to stay ahead of the competition. The Lean Startup approach is one of the most influential methodologies in recent years. This groundbreaking strategy has revolutionized how businesses approach product engineering and product development, helping them create more successful and customer-centric solutions.

The world of product development has witnessed a significant shift, and this change is not just a fleeting trend. Lean Startup has emerged as a fundamental game-changer, and understanding its principles is crucial for anyone involved in product engineering and product development.

In this blog, we will explore its profound impact on the product development process. This introduction to Lean Startup will provide invaluable insights into how this methodology shapes the future of product development.

What is a Lean Startup?

Lean Startup is a revolutionary approach to product development that prioritizes efficiency and customer-centricity. This methodology, optimized for product engineering and product development, aims to minimize waste, maximize learning, and accelerate the delivery of innovative solutions.

By emphasizing rapid iterations, validated learning, and a strong focus on customer feedback, Lean Startup has significantly transformed how businesses create and improve products, resulting in more agile, cost-effective, and successful development processes.

Read our Guide on Agile Methodology: https://www.xcubelabs.com/industry-analysis/

The Principles of Lean Startup

These principles are optimized to streamline product development, enabling businesses to create successful, customer-driven solutions. Here’s a concise overview of these principles:

A. Customer-Centric Approach:

Lean Startup principles focus on a customer-centric approach to product development. This means that entrepreneurs and product teams aim to deeply understand their target audience’s needs, preferences, and pain points.

By listening to customers and empathizing with their experiences, product engineers can create solutions that genuinely address real-world problems. This customer-centric mindset ensures that the resulting product is more likely to succeed in the Market.

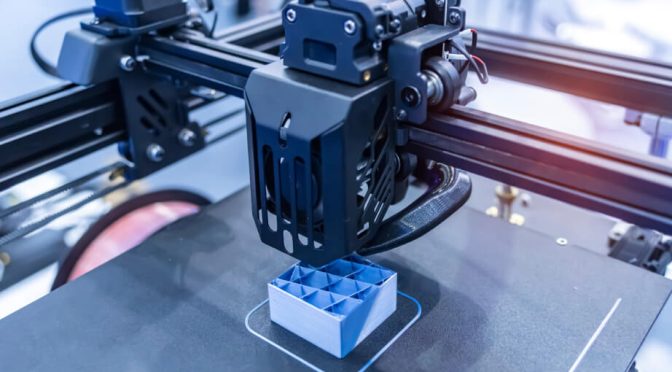

B. Rapid Prototyping and Experimentation:

Speed and agility are essential in product engineering and development. Lean Startup principles advocate for rapid prototyping and experimentation, which involves quickly building simplified product versions (prototypes) and testing them in the real world.

This iterative process allows teams to gather valuable feedback, identify flaws or potential enhancements, and adapt their product accordingly—rapid prototyping and experimentation help minimize risks, conserve resources, and accelerate the product development cycle.

C. Build-Measure-Learn Cycle:

The Build-Measure-Learn cycle is at the core of Lean Startup principles. It represents a continuous loop of activities that starts with building a minimum viable product or prototype, measuring its performance, and learning from the data and insights gathered.

By gathering concrete metrics and customer feedback, product engineers can make informed decisions about the product’s direction. This data-driven approach ensures that development efforts are aligned with customer demands and market realities, reducing the chances of creating products that could be better.

Benefits of Applying Lean Startup in Product Engineering

- Improved Product Development Efficiency

- Enhanced Product Quality

- Minimized Resource Waste

- Increased Adaptability in a Changing Market

Strategies for Implementing Lean Startup in Product Development

A. Validating Assumptions:

Validating assumptions is the cornerstone of Lean Startup methodology in product engineering. By continuously testing and verifying your assumptions about your product and Market, you can ensure that your development efforts align with customer needs and preferences. This data-driven approach minimizes the risk of investing time and resources into features or concepts that may not resonate with your target audience.

B. Minimum Viable Product (MVP):

Creating a Minimum Viable Product (MVP) is an integral part of Lean Startup principles. An MVP is the most streamlined version of your product, allowing you to test core features and gather user feedback.

By building and releasing an MVP, you can quickly enter the Market, gather valuable insights, and make informed decisions about product development. This iterative process saves time and resources and helps fine-tune your product based on user experiences.

C. Pivot and Persevere:

In the dynamic landscape of product development, pivoting or persevering is crucial. Lean Startup encourages entrepreneurs and product engineers to adjust and respond to changing market conditions.

If your initial assumptions or MVP feedback indicate the need for a change in product direction, be willing to pivot and adapt. On the other hand, if your product is gaining traction, persevere and scale your efforts to meet the demands of your developing user base.

Implementing these critical strategies for Lean Startup in product development can enhance your chances of creating successful, customer-focused products while optimizing your product engineering processes for efficiency and innovation.

Also Read: Top product engineering frameworks.

Case studies

A. Case Study

1: Tesla – Transforming Product Development with Lean Startup

Tesla, the electric vehicle (EV) and clean energy company, is a prime example of transforming product development through Lean Startup principles. Tesla’s innovative approach to product engineering has disrupted the automotive industry and set a benchmark for Lean Startup’s success.

Tesla embraced the Lean Startup methodology when developing their first electric car, the Tesla Roadster. Instead of investing massive resources into a traditional, time-consuming product development cycle, they adopted a more agile approach. Here’s how Tesla applied Lean Startup principles to their product engineering:

- Minimum Viable Product (MVP): Tesla started with the Tesla Roadster, a high-end sports car, as their MVP. This allowed them to enter the Market with a product that garnered attention and validation from early adopters.

- Continuous Feedback: Tesla actively sought feedback from Roadster owners, learning from their experiences to refine and improve subsequent models.

- Rapid Iterations: The company iterated quickly, rolling out the Model S, Model X, Model 3, and Model Y quickly. Each iteration incorporated lessons learned and improvements based on customer feedback.

- Validated Learning: Tesla’s approach allowed them to validate the electric vehicle market’s potential and gain valuable insights into consumer preferences and pain points.

- Agile Supply Chain: Tesla also applied Lean principles to its supply chain, ensuring efficient production and cost control, which contributed to their product development success.

B. Case Study

2: Airbnb – Achieving Market Fit through Lean Startup Principles

Airbnb, the online marketplace for lodging and travel experiences, is another example of the Lean Startup model’s success in product engineering. They disrupted the hospitality industry by connecting homeowners with travelers, and their journey started with Lean principles:

- MVP Approach: Airbnb launched its platform with a simple website that allowed hosts to list their properties. This minimalistic approach helped them test the Market with minimal investment.

- Customer Feedback: The founders actively engaged with hosts and guests, collecting customer feedback and adapting the platform to address user needs and pain points.

- Pivot and Iteration: Airbnb initially focused on renting air mattresses in people’s homes but later pivoted to the broader home-sharing Market, demonstrating flexibility and adaptability.

- Scalable Technology: As Airbnb expanded, it focused on building a scalable and user-friendly platform to handle the growing demand.

- Achieving Market Fit: Through constant iterations and listening to its users, Airbnb acquired product-market fit and became a global industry disruptor.

In both cases, Tesla and Airbnb applied Lean Startup principles to streamline product engineering and development processes. By staying focused on delivering value to customers, actively seeking feedback, and iterating rapidly, they revolutionized their respective industries and achieved extraordinary success. These real-world examples underscore the effectiveness of the Lean Startup model in product engineering and product development.

Frequently Asked Questions

1. What are the five principles of lean startup?

The five principles of Lean Startup are: (1) Entrepreneurs are everywhere; (2) Entrepreneurship is management; (3) Validated learning; (4) Build-Measure-Learn; and (5) Innovation accounting.

2. What is The Lean Startup example?

Dropbox is an example of a Lean Startup. The company initially created a simple video demonstrating the concept to gauge interest and validate demand before fully developing the product.

3. Is lean startup still relevant?

Yes, Lean Startup is still relevant. Its principles guide startups and established companies in navigating uncertainties, testing assumptions, and optimizing resource allocation.

4. What is the criticism of The Lean Startup?

Criticisms of the Lean Startup include an overemphasis on rapid experimentation at the expense of thorough planning, the potential for premature scaling based on flawed assumptions, and the challenge of applying its principles in industries with long development cycles or regulatory constraints.

Outcome

In conclusion, the Lean Startup methodology, summarized as the lean startup summary, has had a profound and transformative impact on product engineering and development. This innovative approach, which emphasizes rapid iteration, customer feedback, and a focus on building a minimum viable product (MVP), has ushered in a new era of efficiency and effectiveness in product development. By prioritizing experimentation, learning, and adaptation, businesses can mitigate risk, accelerate time-to-market, and increase the likelihood of creating successful products that meet customers’ evolving needs.

One key benefit of adopting the Lean Startup model principles in product engineering is reducing waste. By continuously testing and refining ideas, products can be developed with a more streamlined and cost-effective process. This saves time and resources and minimizes the risk of investing heavily in a product that may not resonate with the target market.

Additionally, a significant focus of the Lean Startup business plan is validation and customer feedback. Goods are conceived and developed with a focus on the wants and preferences of the consumer with this customer-centric approach in mind. Through continuous consumer feedback gathering and integration, product engineers may create solutions with a higher chance of commercial success.

Another essential part of Lean Startup’s influence on product development is the minimal viable product (MVP) idea. Teams can acquire knowledge fast and adjust to real-world user interactions when they construct a rudimentary product version and take it to Market early. This iterative process makes more informed decision-making and quicker product development possible.

Introducing the concept of a Lean Startup business plan to develop new products has also encouraged entrepreneurship and creativity inside companies. It pushes groups to try out novel concepts, take measured chances, and accept failure as a tool for growth. The approach to product engineering has become more dynamic and responsive due to this cultural transformation.

![Blog-[x]cube LABS](https://d6fiz9tmzg8gn.cloudfront.net/wp-content/uploads/2016/06/blog_banner.jpg)